- Welcome to our website

- Email:[email protected]

- Email:[email protected]

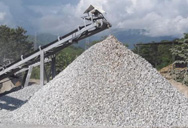

ponce crusher machine design

- Accueil

- >

- ponce crusher machine design

ponce crusher machine design

ponce crusher machine design :

Small Scale Mechanized Stone Crusher, Mechanical Design

2021年7月26日 The purpose of this project is to evaluate the kinematic and static force analysis of a single toggle jaw crusher that employs the simple technology of a four bar

Consulter un spécialiste

(PDF) DESIGN OF MECHANICAL CRUSHING

Design and Fabrication of Pedal Operated Chilli Crusher Machine. International Journal on Recent and Innovation Trends in Computing and

Consulter un spécialiste

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to

Consulter un spécialiste

Design of a crushing system that improves the crushing

2016年2月10日 This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour. There are three main steps in

Consulter un spécialiste

CONE CRUSHER MODELLING AND SIMULATION

2019年7月3日 mining industry. The cone crusher concept was developed in the early 20th century and the basic layout of the machine has not changed dramatically since then.

Consulter un spécialiste

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

2012年7月4日 Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which

Consulter un spécialiste

A review of modeling and control strategies for cone crushers

2021年8月15日 open access. Highlights. •. We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. •. The steady-state model

Consulter un spécialiste

(PDF) Design of Impact Stone crusher machine - Academia

THESIS. DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER 1- 2017 •. Ibrahim Sulaiman. Crushers are needed in a lot of industries for the sole purpose of

Consulter un spécialiste

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 Jaw, gyratory, cone and roller crushers are all examples of crusher machines that utilize form conditioned compression to achieve size reduction. There is an essential and important

Consulter un spécialiste

Shadab Husain , Mohammad Shadab Sheikh - IOSR

2013年12月17日 Fig.Design of Can Crusher Machine III. DESIGN AND CONSTRUCTION 3.1 Pulleys and Shafts The can crusher consists of four pulleys, two of which are smaller pulleys having the same diameter of 81 mm and there are two bigger pulleys one of them is connected to the main shaft having a diameter of 11

Consulter un spécialiste

Crushing Machine Design for Wood Waste Utilization

design that meets all of the workers' needs and expectations. The result of this study suggested the development of a multiplex and blockboard waste crushing machine, which offers a number of benefits over existing wood crusher machines, including the ability to produce finer sawdust in accordance with MDF raw material criteria (0,43 g/m3).

Consulter un spécialiste

Machines Free Full-Text Study on Plant

2022年7月12日 Soil blocking and plant entanglement are the main challenges in Cyperus esculentus harvesting and excavating. The structure of the rotary blade is one of the critical factors affecting plant crushing

Consulter un spécialiste

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 The size reduction obtained by a jaw crusher is form conditioned crushing due to the nature of the machine. There are two main types of jaw crushers, single toggle and double toggle. The difference being the resulting motion of the jaw depending on the design (Wills and Napier-Munn, 2015).

Consulter un spécialiste

IOP Conference Series: Earth and Environmental Science

in Figure 3. The designed organic waste crusher uses gasoline and organic waste as an energy source and material input, respectively. The output of the machine is in the forms of noise, vibration, heat and finer of organic waste. Figure 3. Schematic diagram of the crusher. 3.2. Mechanical design 3.2.1. Blade.

Consulter un spécialiste

ballast crushing machine design pdf small sand gravel

\n \n crusher design ballast antoonmahieu \n. ballast crusher,ballast crusher machine,ballast2018 8 31 #183 introduction of ballast crusher.1.when it comes to the ballast,it refers to the heavy material,such as gravel,sand,iron,or coarse stone,placed low in a vessel to form the bed of a railroad track or road to improve its stability is widely used

Consulter un spécialiste

Design and Fabrication of Plastic Bottle Crushing

2023年6月6日 Design of a Plastic Bottle Crusher” “International Journal of Scientific Technology Research (IJSTR)” ISSN 2277-8616, volume 3, issue 7, Page 61-63, July 2014. [8] Mr. Mit Shah, Published Paper on, Design Consideration in an Automatic Can/Plastic Bottle Crusher Machine, ISSN 2091-2730.

Consulter un spécialiste

(PDF) Design of Impact stone crusher machine - ResearchGate

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. ... Machine Design 14th ed. USA, 2005. [5] D.G ...

Consulter un spécialiste

Machine Design Part I Course (Georgia Tech) Coursera

There are 5 modules in this course. “Machine Design Part I” is the first course in an in-depth three course series of “Machine Design.”. The “Machine Design” Coursera series covers fundamental mechanical design topics, such as static and fatigue failure theories, the analysis of shafts, fasteners, and gears, and the design of ...

Consulter un spécialiste

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing.

Consulter un spécialiste

Design and Construction of Aluminum Cans Crushing

2022年10月7日 and validation of the machine indicated that the crusher operated well. Khanapure et al. (2015) designed and fabricated Dual Stroke Aluminum Can Crusher. The special feature of the design is the automatic removal of crushed Cans from the crushing point and the automatic feeding of Cans to be crushed.

Consulter un spécialiste

Advanced Beverage Can Crusher Machines: A Review - TRP

2020年11月7日 components of the machine would be operated. After the design has been completed, the tests are carried out. El-Zomoret al[73] presented a Can crusher machine using a scotch yoke mechanism with a multi or two side crushing capability. Such a Can crusher machine is used only for the crushing of aluminum Cans. The scotch yoke

Consulter un spécialiste

Design of a Multi-Purpose Crushing Machine for

primary function of the multipurpose crusher, which is grain size reduction. The multi-purpose machine design drawings were developed using AUTOCARD 2015 version. 2.1 Design Parameters The following parameters were taken into consideration during the design stages of the multi-purpose crushing machine for processing of food grains.

Consulter un spécialiste

Volume I Fundamentals of Machine Design - Cambridge

2017年6月29日 Fundamentals of Machine Design Volume I Machine design is a part of Engineering Design. Fundamentals of Machine Design is compiled in two volumes. Vol. I provides extensive coverage and comprehensive discussion on the fundamental concepts and processes of machine design. Unit 1 of this volume starts by giving a background to

Consulter un spécialiste

Fabrication of Aluminium Can Crusher by Hydraulic

2019年3月2日 the crusher considering forces required for crushing and ergonomic factor that an operator needs. The design of this machine is such that it would require optimum load to crush metals and will not strain the user or operator. After the completion of design process, it is manufactured and transformed into a machine that would help in waste ...

Consulter un spécialiste

Plastic Waste Management System Using Metal Shredder for

2022年8月16日 With the high rise in population and a huge level of unwanted materials, conventional methods of waste disposal are becoming outdated as it involves more manual scavenging work and unwanted human potential. In order to overcome the above manual issues, there is a need to design a machine that can clear the litter and leftover wastes

Consulter un spécialiste

Design and Fabrication of Pneumatic Can Crushing

2024年1月10日 International Journal of Advances in Scientific Research and Engineering (ijasre) E -ISSN : 2454 8006 DOI: 10.31695/IJASRE.2020.33914 Volume 6, Issue 10 October - 2020

Consulter un spécialiste

Design and Fabrication of Pneumatic Can Crushing

This paper deals with the operations, the design and structural analysis of can crusher. A Can crusher is a device to reduce large material object into a smaller volume. The crusher reduces the size or change the form of waste materials so that they can be disposed off or recycled easily. The Can crushing machine is designed to crush aluminum waste

Consulter un spécialiste

Output prediction of cone crushers - ScienceDirect

1998年3月1日 Printed in Great Britain 0892-.6875/98 $19.004-0.00 OUTPUT PREDICTION OF CONE CRUSHERS C.M. EVERTSSON Machine and Vehicle Design, Chalmers University of Technology, S-412 96 G6teborg, Sweden. ... 7. . REFERENCES Evertsson, C.M., Prediction of Size Distributions from Compressing Crusher Machines, Proceedings

Consulter un spécialiste

IOP Conference Series: Materials Science and

1.2 Project Scope: This project is limited to the scope as follows; Research, Design and Fabrication of Mini Plastic Shredder Machine. Test-run and verify the Machine. Research and suggest the safe protection during process. Reduce the plastic. As a solution, a medium-sized machine has been developed. 2.

Consulter un spécialiste

- broyeur à boulets ratio de balle optimale

- dép ts de sable de silice en Inde

- broyeurs pour la granulation

- roche petite échelle concasseur

- finlay mâchoire sortie de concasseur canana

- bonheur eliminateur broyeur a marteaux

- l'exploitation minière et de broyage de minerai de fer

- Charbon de concassage et de configuration de l'usine de dépistage

- minerai de fer concasseur à machines en Sénégal

- concasseur grès 250 th marque chinoise prix

- machines de transformation de cacao

- l extraction du charbon dans les collines de Jaintia

- le minerai de fer et de son enrichissement

- maquinas para moer milho

- concasseurs mâchoires gcv